New home builders come in many shapes and sizes, from those who specialise in custom, high-end construction to those who offer inexpensive, ready-to-move-in, one-of-a-kind homes. So whether you’re looking for a Tact home or a custom-built, single-family house, it’s essential to know what you’re getting into before you make a decision.

Price ranges

Price ranges

It pays to know the construction cost before you commit if you want to build a new home. The costs will vary based on your geographic location, home size, and the materials you choose. However, the average price of building a new house will generally be between $163,333 and $483,868. In most cases, you will be able to get a quality home in the middle of the pack.

The price of materials, the labour required to build it, and the cost of your mortgage are just a few factors to consider. Traditionally, it takes about six months to build a home. But you may have to wait a few extra months due to a shortage of skilled labour.

The most expensive material to use in a home may be land. While this factor is not included in the price of a new home, it can add up quickly. It can include the cost of acquiring the land and its associated utilities. Therefore, using the right kind of land can be an excellent way to save money in the long run. Alternatively, you could use a pre-built home if your budget is tight.

Another thing to consider is the design and finishes. The tiniest detail can make a massive difference in the overall price of your new house. Likewise, using the right colours and finishes can improve your new place’s look and feel. Lastly, the location is also a significant consideration. For example, if you want to live in a fancy neighbourhood, building your home will be more expensive than living in a more rural setting. Learn more from the IKON-Homes new home builders Auckland.

Ultimately, the actual cost of building a new home depends on your budget and needs. For example, a two-bedroom bungalow could cost around $150 per square foot, but a high-end luxury home could cost hundreds of thousands. Fortunately, many options exist for building a new home in this market. Choosing the right home builders can avoid a lot of stress and expense.

Custom vs Production

Knowing the difference between custom and production new home builders is essential if you’re planning a new home. Choosing the right builder can result in a house you’re happier with. Unfortunately, it can also cost you money and time.

Generally, custom homes are more expensive than production homes. It is because you must choose an architect, designer, and contractor. They also require a more extensive design process, which takes more time.

On the other hand, production home builders can deliver a new home for less. These builders use a catalogue of floor plans and building materials to create an entire development simultaneously.

Unlike custom builders, production home builders will not allow you to customise your home’s features. So, for example, you can add a breakfast nook, but you’ll be limited to the size of windows and walls.

In addition to having fewer customisation options, production homes will typically be built in large master-planned communities. Many of these communities sit in areas with cheaper land, which can also save you money.

Most production home builders work with large-volume builders. Because of the high volume, they can buy materials at a reduced cost. They can then pass these savings on to the homebuyer.

Production homes are typically built in large, suburban neighbourhoods. Their communities will have a model home, a selection of floor plans, and optional features. The community will also have a developer who will oversee the construction of the houses.

Production builders are also known as “high capacity” builders. Their economies of scale enable them to purchase materials at a reduced price and negotiate deals.

While they offer fewer design choices than custom builders, they can still create a unique home. Of course, you’ll have more input during the construction phase, but you won’t be able to make all the decisions. Learn more from the IKON-Homes new home builders Auckland.

To decide which type of home builder is best for you, consider how much input you’re willing to give and whether you prefer to build a single home or a series of homes. Custom homes are usually the most expensive, but they offer a higher degree of control over the resale value of your new home.

Timelines

When building a new home, there are many factors to consider. Location, style, and type of home are all important factors. In addition, having a solid timeline for your project can help you keep track of the process and make it less stressful.

The first step in building a new home is to prepare the site for construction. It involves levelling the land and clearing any obstructions. Once the site is ready, the contractor will plan the house’s layout. Next, they will use heavy equipment to clear the area, remove debris, and level the ground.

The contractor will add plumbing, wiring, and insulation to the house during this stage. They will also begin installing cabinets and flooring. Finally, they will install a heating, ventilating, and air conditioning (HVAC) system.

Typically, building a new home takes about eight months. However, it can take longer, depending on several factors. For example, custom homes may require additional time to create plans and secure financing. Plus, weather can affect the process. Therefore, if you live in a region susceptible to winter weather, you must plan to ensure that your home is completed before the weather turns bad.

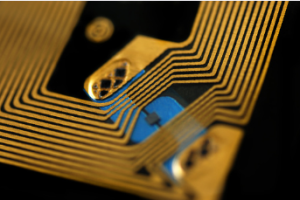

The choice between active vs passive RFID tags for asset tracking will depend on the types of assets being tracked, as well as the application of the technology. For example, passive tags are used for monitoring small items, while active tags are more suited for tracking more significant objects. For professional RFID asset tracking services, check out

The choice between active vs passive RFID tags for asset tracking will depend on the types of assets being tracked, as well as the application of the technology. For example, passive tags are used for monitoring small items, while active tags are more suited for tracking more significant objects. For professional RFID asset tracking services, check out  Fluorine-treated PET bottles are used for the Covid-19 pandemic

Fluorine-treated PET bottles are used for the Covid-19 pandemic Whether you’re trying to advertise a new product or launch a new campaign, a well-designed, well-placed letter will do the trick. There are several options to choose from, and they range from classic to quirky. Luckily, it’s easy to figure out which ones are best for your business. A quick web search will provide all the information you need to make an educated choice. After all, you’re looking for the perfect letter for your needs. Using the right combination of fonts and paper types will ensure a professional-looking piece that’s sure to get the job done. Learn more about

Whether you’re trying to advertise a new product or launch a new campaign, a well-designed, well-placed letter will do the trick. There are several options to choose from, and they range from classic to quirky. Luckily, it’s easy to figure out which ones are best for your business. A quick web search will provide all the information you need to make an educated choice. After all, you’re looking for the perfect letter for your needs. Using the right combination of fonts and paper types will ensure a professional-looking piece that’s sure to get the job done. Learn more about